YTI Terminal: Enhancing Productivity in Yard and Terminal Operations

Understanding YTI Terminal

Overview and History

YTI (Yusen Terminals International) Terminal is a state-of-the-art container terminal located in the Port of Los Angeles. Known for its commitment to efficiency and innovation, YTI has become a benchmark for productivity in yard and terminal operations.

Key Facts:

- Established: [Insert Year]

- Annual Container Volume: [Insert Latest Data]

- Terminal Area: [Insert Size]

- Berth Length: [Insert Length]

YTI’s Unique Approach

YTI Terminal stands out due to its:

- Advanced technology integration

- Commitment to environmental sustainability

- Focus on continuous improvement and employee development

- Strategic partnerships with shipping lines and logistics providers

Strategies for Enhancing Yard Productivity

1. Optimize Yard Layout and Space Utilization

YTI Terminal has implemented several strategies to maximize space efficiency:

- Dynamic Yard Planning: Utilizing AI-driven software to optimize container placement based on ship schedules and cargo characteristics.

- Vertical Stacking: Implementing advanced stacking techniques to increase storage capacity without expanding the physical footprint.

- Dedicated Areas: Creating specialized zones for different types of cargo (e.g., refrigerated containers, hazardous materials) to streamline operations.

2. Implement Advanced Equipment and Automation

YTI has invested heavily in cutting-edge equipment to boost productivity:

- Automated Stacking Cranes (ASCs): Deploying ASCs to manage container stacks with minimal human intervention.

- Optical Character Recognition (OCR) Gates: Streamlining gate operations with automated identification and processing of trucks and containers.

- Automated Guided Vehicles (AGVs): Utilizing AGVs for efficient horizontal transportation within the terminal.

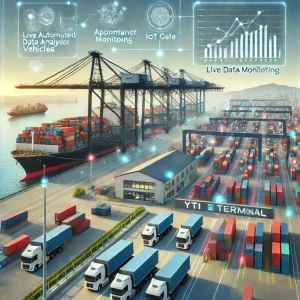

3. Leverage Data Analytics and IoT

YTI Terminal harnesses the power of data to drive decision-making:

- Real-time Tracking: Implementing IoT sensors on equipment and containers for live monitoring of terminal operations.

- Predictive Maintenance: Using data analytics to forecast equipment maintenance needs, reducing downtime.

- Performance Dashboards: Developing comprehensive dashboards to track KPIs and identify areas for improvement.

4. Enhance Gate Operations

Efficient gate management is crucial for overall terminal productivity:

- Pre-Gate Systems: Implementing digital pre-gate processes to reduce truck waiting times.

- Appointment Systems: Utilizing advanced scheduling software to manage truck arrivals and reduce congestion.

- Mobile Apps for Drivers: Developing user-friendly apps to provide real-time information and updates to truck drivers.

5. Optimize Vessel Operations

YTI Terminal focuses on minimizing vessel turnaround times:

- Berth Planning Optimization: Using advanced algorithms to optimize berth allocation and minimize vessel waiting times.

- Dual-Cycle Operations: Implementing simultaneous loading and unloading processes to reduce vessel time at berth.

- Crane Productivity Enhancements: Investing in faster, more efficient cranes and providing ongoing operator training.

Case Studies: YTI Success Stories

Case Study 1: Automated Gate System Implementation

Challenge: Long truck queues and inefficient gate processing.

Solution:

- Implemented OCR technology and automated gate kiosks

- Integrated with Terminal Operating System (TOS) for seamless data flow

- Provided driver education and support during transition

Results:

- 50% reduction in gate processing times

- 30% decrease in truck turn times

- Improved data accuracy and security

Case Study 2: Yard Density Optimization Project

Challenge: Limited yard space and increasing container volumes.

Solution:

- Implemented advanced yard planning software

- Redesigned yard layout based on data analysis

- Introduced automated stacking cranes in key areas

Results:

- 25% increase in yard capacity without physical expansion

- 20% improvement in container retrieval times

- Reduced equipment travel distances by 15%

Overcoming Challenges in Terminal Productivity Enhancement

1. Resistance to Change

Challenge: Employee reluctance to adopt new technologies and processes.

Solution:

- Implement comprehensive change management programs

- Provide extensive training and support

- Involve employees in the planning and implementation processes

2. High Initial Investment Costs

Challenge: Securing funding for large-scale technology and equipment upgrades.

Solution:

- Develop a phased implementation plan

- Conduct thorough cost-benefit analyses to justify investments

- Explore public-private partnerships and government grants

3. Integration of Legacy Systems

Challenge: Ensuring new technologies work seamlessly with existing systems.

Solution:

- Conduct thorough systems audits before implementation

- Choose flexible, API-driven solutions that can integrate with various platforms

- Implement robust testing procedures before full deployment

4. Cybersecurity Concerns

Challenge: Protecting sensitive data and operations from cyber threats.

Solution:

- Implement multi-layered security protocols

- Conduct regular security audits and penetration testing

- Provide ongoing cybersecurity training for all staff

Future Trends in Terminal Operations

- Artificial Intelligence and Machine Learning: Advanced predictive analytics for demand forecasting and resource allocation.

- 5G Technology: Ultra-fast, low-latency communications enabling real-time decision-making and control.

- Autonomous Vehicles: Fully autonomous container handling equipment and trucks within the terminal.

- Blockchain Integration: Enhanced transparency and security in documentation and cargo tracking.

- Green Technologies: Implementation of zero-emission equipment and renewable energy sources.

Measuring Terminal Productivity

To assess the effectiveness of productivity enhancement strategies, YTI Terminal tracks these key performance indicators (KPIs):

- Container moves per hour (gross and net)

- Truck turnaround time

- Vessel turnaround time

- Yard utilization rate

- Equipment utilization and downtime

- Energy consumption per TEU handled

- Safety incidents and near-misses

Best Practices for Implementing Productivity Enhancements

- Start with a Comprehensive Audit: Assess current operations to identify key areas for improvement.

- Set Clear, Measurable Goals: Establish specific targets for productivity enhancements.

- Prioritize Projects: Focus on initiatives that offer the highest ROI and align with long-term strategic objectives.

- Invest in Employee Development: Provide ongoing training and create a culture of continuous improvement.

- Foster Collaboration: Work closely with shipping lines, trucking companies, and other stakeholders to align improvements across the supply chain.

- Regularly Benchmark Performance: Compare your terminal’s performance against industry leaders and adjust strategies accordingly.

- Stay Informed: Keep abreast of technological advancements and industry trends to maintain a competitive edge.

Conclusion

Enhancing productivity in yard and terminal operations is an ongoing process that requires a combination of strategic planning, technological innovation, and a commitment to continuous improvement. YTI Terminal’s success in this area serves as a valuable model for terminal managers looking to optimize their operations.

By implementing the strategies outlined in this guide, terminals can significantly improve their efficiency, reduce costs, and enhance their competitive position in the global maritime logistics landscape. Remember that every terminal is unique, and strategies should be tailored to fit specific operational contexts and challenges.

As the industry continues to evolve, staying adaptable and open to new technologies and processes will be key to maintaining and improving productivity. Terminal managers who embrace innovation, prioritize data-driven decision-making, and foster a culture of continuous improvement will be well-positioned to lead their facilities to new heights of operational excellence.