An In-Depth Guide to What Is a Lift Gate

This article provides a detailed explanation of, highlighting their key features, practical applications, and relevance for professionals and businesses.

What Is a Lift Gate?

A lift gate is a hydraulic or electric-powered platform mounted on the back of a truck, trailer, or delivery vehicle. It raises and lowers heavy cargo between the ground and the truck bed, reducing the need for manual lifting or forklift assistance.

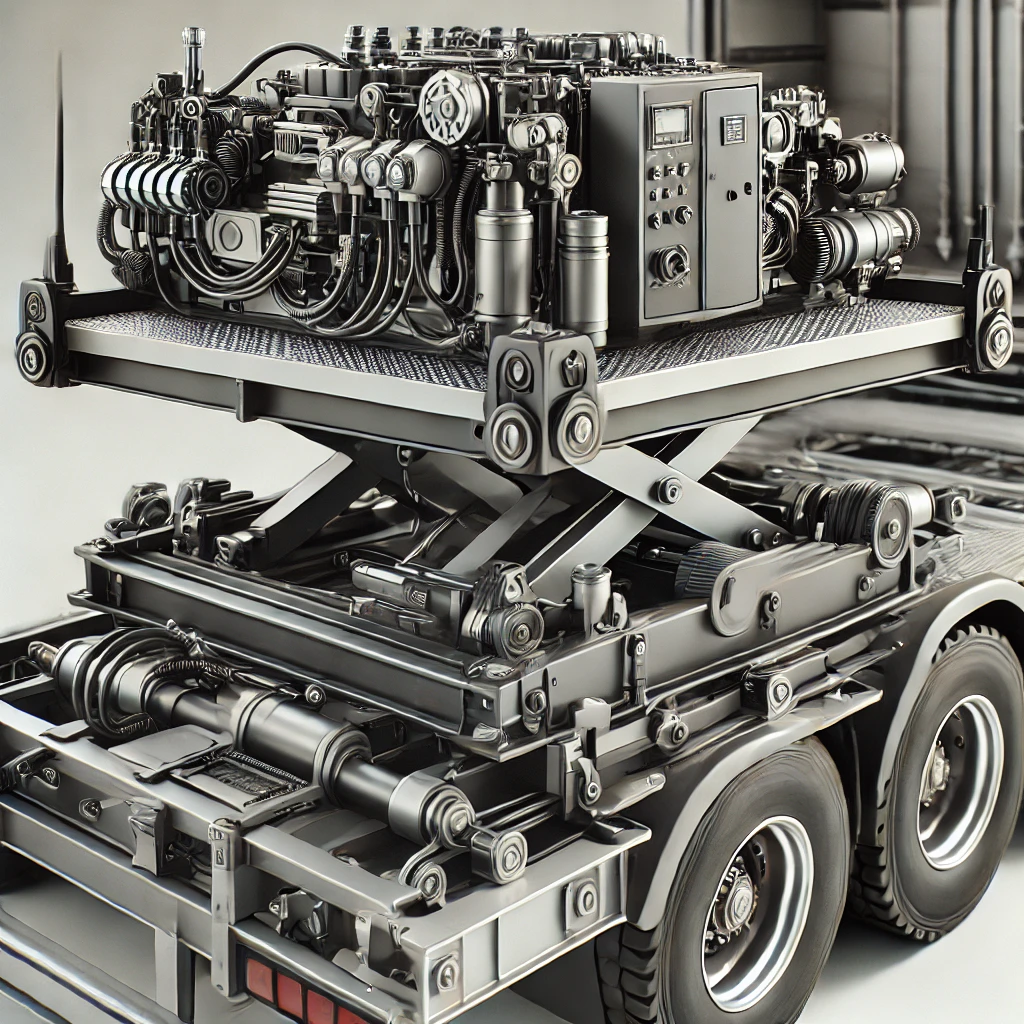

Key Lift Gate Components

Component | Function |

Platform | The flat surface that holds cargo while being lifted or lowered. |

Hydraulic System | Powers the lift mechanism for smooth operation. |

Control Panel | Allows the operator to raise or lower the lift gate. |

Safety Rails & Locks | Prevents cargo from slipping during movement. |

Key Features

1. Reduces Manual Lifting & Labor Costs

- Eliminates the need for manual heavy lifting.

- Reduces the risk of workplace injuries.

2. Increases Delivery Efficiency

- Allows quick and safe cargo transfers without forklifts.

- Essential for non-dock deliveries at businesses or residential locations.

3. Supports Various Cargo Types

- Handles palletized goods, furniture, appliances, and machinery.

- Can lift several thousand pounds depending on the model.

4. Compatible with Different Truck Types

- Available for box trucks, flatbed trucks, and semi-trailers.

- Customizable based on cargo size and weight requirements.

5. Remote & Manual Operation Options

- Some models feature wireless remotes for enhanced control.

- Manual backup systems ensure operation in case of power failure.

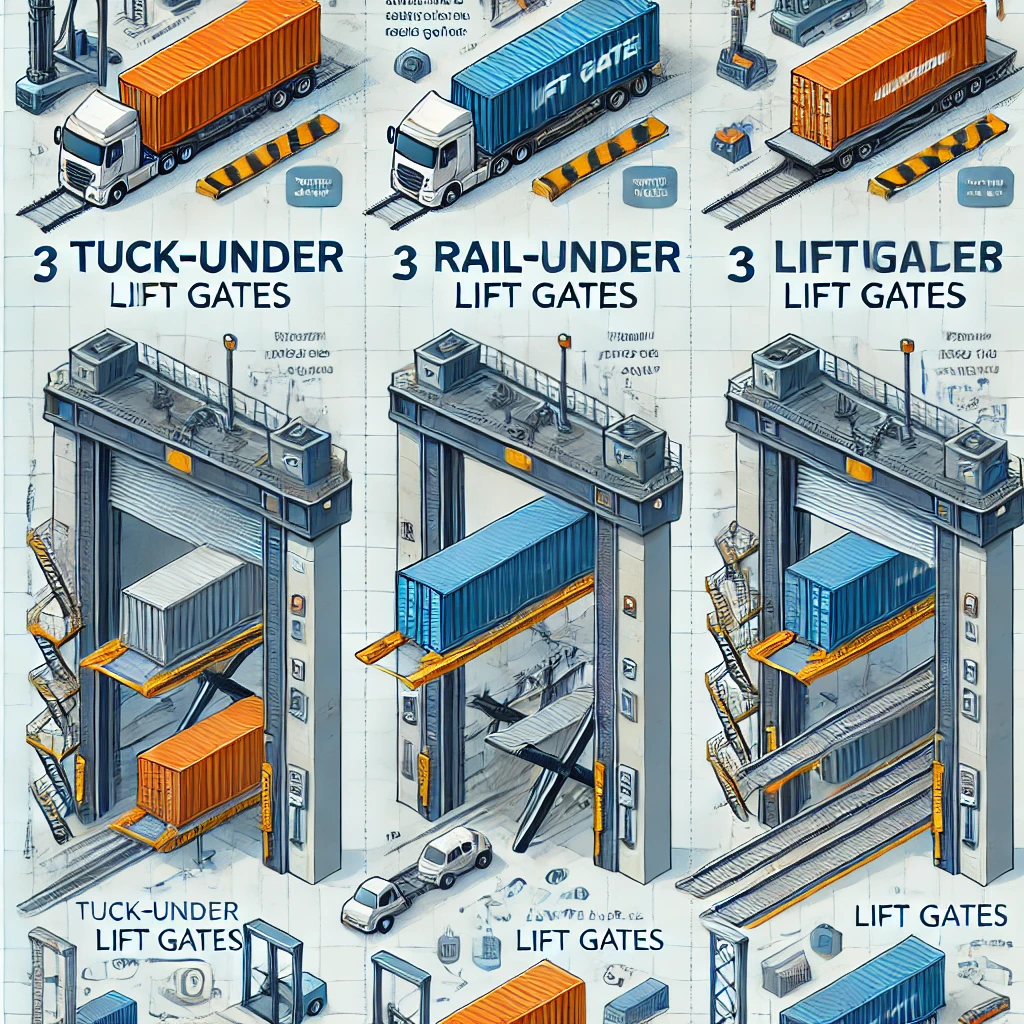

Types of Lift Gates

Lift Gate Type | Description | Best Used For |

Tuck-Under Lift Gate | Folds under the truck when not in use. | General freight, delivery services. |

Rail Lift Gate | Moves vertically along the back of the truck. | Heavy equipment, palletized loads. |

Cantilever | Tilts and adjusts to different angles. | Fragile items, precise unloading. |

Column | Operates on vertical rails for high stability. | Large cargo, warehouse distribution. |

Practical Uses

1. Freight & Logistics Industry

- Common in LTL (Less-Than-Truckload) shipping for non-dock deliveries.

2. Retail & E-Commerce Distribution

- Ideal for delivering furniture, appliances, and electronics.

3. Construction & Industrial Equipment Handling

- Used for transporting heavy tools, machinery, and bulk materials.

4. Moving & Relocation Services

- Ensures safe loading/unloading of household or office furniture.

5. Medical & Pharmaceutical Shipments

- Essential for handling delicate medical equipment and supplies.

Advantages and Challenges of Using

Advantages | Challenges |

Reduces labor costs and physical strain on workers. | Requires additional truck space when installed. |

Increases efficiency for non-dock deliveries. | Weight capacity limitations vary by model. |

Prevents cargo damage with smooth lifting mechanisms. | Additional maintenance needed for hydraulic systems. |

Improves driver safety by reducing manual lifting. | Not always necessary for dock-to-dock shipments. |

Lift Gate vs. Forklift: Which One to Use?

Feature | Lift Gate | Forklift |

Operation | Attached to a truck, raises cargo up/down. | Independent vehicle for warehouse loading. |

Best For | Deliveries to locations without docks. | Large warehouses, high-volume operations. |

Mobility | Fixed to the truck. | Moves freely within storage areas. |

Lifting Capacity | Limited to a few thousand pounds. | Higher capacity for bulk cargo. |

When to Use a Lift Gate?

- Best for deliveries to businesses or homes without loading docks.

- Essential for handling large, heavy, or fragile shipments.

- Recommended for companies with small delivery teams.

- Not necessary for warehouse-to-warehouse shipments with forklifts.

Conclusion

A lift gate is a valuable tool for freight carriers, delivery services, and businesses that regularly transport heavy cargo. It improves safety, efficiency, and convenience, making it an essential addition to trucks handling non-dock deliveries.

By understanding lift gate types, features, and applications, businesses can streamline their supply chain, reduce labor costs, and enhance delivery operations. Whether you’re a logistics provider, retailer, or manufacturer, investing in a lift gate-equipped truck can significantly improve cargo handling efficiency.