West Basin Container Terminal: WBCT Global Trade

Understanding West Basin Container Terminal

Overview and Strategic Importance

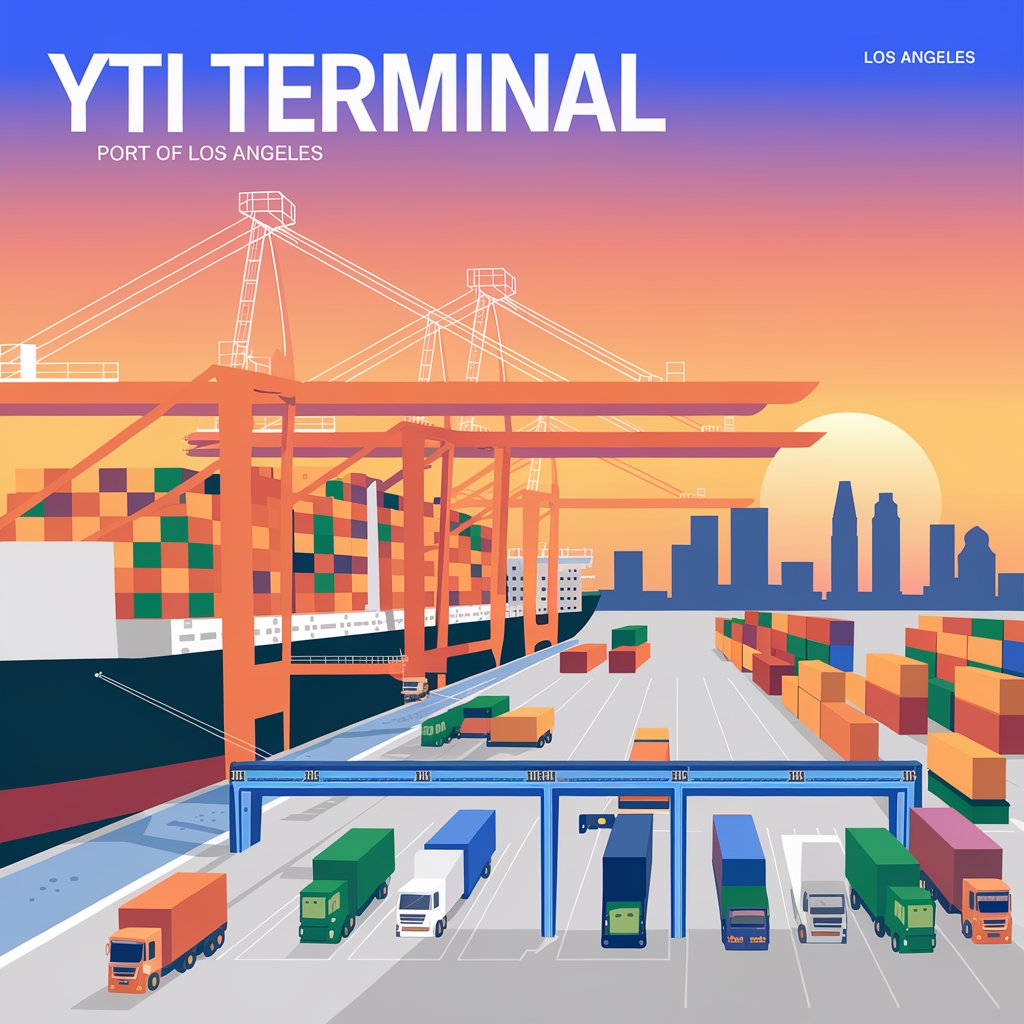

West Basin Container Terminal is a state-of-the-art facility that serves as a gateway for trans-Pacific trade. Its strategic location and advanced capabilities make it a critical component of the Pacific Coast shipping infrastructure.

Key Facts:

- Location: Port of Los Angeles, California

- Operated by: [Insert current operator]

- Annual Container Volume: [Insert latest data] TEUs

- Terminal Area: [Insert size] acres

- Berth Length: [Insert length] feet

WBCT’s Competitive Advantages

- Deep-water berths capable of handling mega-container vessels

- Advanced cargo-handling equipment

- Excellent intermodal connections

- Commitment to environmental sustainability

- Strategic partnerships with major shipping lines

Streamlining Operations at West Basin Container Terminal

1. Advanced Terminal Operating System (TOS)

WBCT global trade utilizes a cutting-edge TOS to optimize various aspects of terminal operations:

- Real-time Tracking: Provides instant visibility of container locations and movements

- Automated Planning: Optimizes yard space utilization and container stacking

- Integration: Seamlessly connects with customs, trucking, and rail systems

2. Efficient Gate Operations

To minimize truck turn times and reduce congestion, WBCT has implemented:

- Automated Gate System: Utilizes OCR technology for quick and accurate truck and container identification

- Appointment System: Allows truckers to schedule pick-ups and drop-offs, balancing terminal workload

- Extended Gate Hours: Offers night and weekend gate operations to spread out truck traffic

3. Optimized Vessel Operations

WBCT focuses on minimizing vessel turnaround times through:

- Berth Planning Software: Optimizes berth allocation and minimizes vessel waiting times

- Dual-Cycle Operations: Implements simultaneous loading and unloading to reduce vessel time at berth

- High-Performance Cranes: Utilizes super post-Panamax cranes for faster container handling

4. Intermodal Efficiency

The terminal leverages its strategic location to offer seamless intermodal connections:

- On-dock Rail Facility: Provides direct rail access for efficient cargo transfer

- Near-dock Rail Yards: Offers additional capacity for rail operations

- Dedicated Trucking Lanes: Ensures smooth flow of containers to and from the terminal

5. Technology Integration

WBCT embraces technology to enhance operational efficiency:

- IoT Sensors: Monitors equipment performance and container conditions in real-time

- Data Analytics: Utilizes big data to predict trends and optimize resource allocation

- Mobile Apps: Provides stakeholders with real-time information and updates

Case Studies: Successful Operations at WBCT global trade

Case Study 1: Mega-Vessel Handling

Challenge: Accommodating increasing sizes of container vessels.

Solution:

- Invested in larger cranes with extended reach

- Implemented advanced berth planning systems

- Enhanced yard operations to handle larger container volumes

Results:

- 30% increase in container moves per vessel call

- 25% reduction in vessel turnaround time for mega-ships

Case Study 2: Peak Season Management

Challenge: Managing surge in container volumes during peak shipping season.

Solution:

- Implemented predictive analytics for resource planning

- Extended gate hours and increased workforce during peak periods

- Collaborated with trucking companies for better coordination

Results:

- Maintained average truck turn times despite 40% volume increase

- Reduced container dwell times by 20% during peak season

Overcoming Operational Challenges at WBCT global trade

1. Congestion Management

Challenge: Handling increasing container volumes without compromising efficiency.

Solution:

- Implement dynamic yard planning algorithms

- Enhance intermodal connections to expedite container movement

- Utilize off-dock storage facilities during peak periods

2. Environmental Compliance WBCT global trade

Challenge: Meeting stringent environmental regulations while maintaining operational efficiency.

Solution:

- Invest in clean energy equipment (e.g., electric cranes, hybrid vehicles)

- Implement vessel speed reduction programs

- Optimize truck routing to reduce emissions

3. Labor Relations WBCT global trade

Challenge: Balancing automation with workforce concerns.

Solution:

- Engage in open dialogue with labor unions

- Provide training programs for new technologies

- Implement gradual automation with clear communication

4. Cybersecurity for WBCT global trade

Challenge: Protecting sensitive operational data from cyber threats.

Solution:

- Implement robust cybersecurity protocols

- Conduct regular security audits and employee training

- Establish secure data sharing mechanisms with stakeholders

Future Trends Impacting WBCT Operations

- Autonomous Vehicles: Integration of self-driving trucks and automated guided vehicles (AGVs) within the terminal

- Blockchain Technology: Enhanced transparency and security in documentation and cargo tracking

- Artificial Intelligence: Advanced predictive analytics for optimizing terminal operations

- 5G Connectivity: Ultra-fast, low-latency communications enabling real-time decision-making

- Green Technologies: Continued focus on zero-emission equipment and sustainable practices

Key Performance Indicators (KPIs) for WBCT

To measure operational efficiency, WBCT focuses on these key metrics:

- Vessel Turnaround Time

- Container Moves Per Hour (Gross and Net)

- Truck Turn Time

- Container Dwell Time

- Berth Utilization Rate

- Equipment Utilization and Downtime

- Energy Consumption Per TEU Handled

Best Practices for Shippers Using WBCT

- Leverage Technology: Utilize WBCT’s digital platforms for real-time tracking and updates

- Plan Ahead: Use the appointment system to schedule container pick-ups and drop-offs during optimal times

- Optimize Container Loading: Maximize container utilization to reduce the number of moves required

- Consider Intermodal Options: Take advantage of WBCT’s rail connections for inland transportation

- Stay Informed: Keep abreast of WBCT’s operational updates and policy changes

- Collaborate: Work closely with terminal operators to address any issues promptly

- Use Off-Peak Hours: When possible, schedule operations during less busy periods to reduce wait times

Comparative Analysis: WBCT vs. Other Pacific Coast Terminals

Feature | West Basin Container Terminal | Other Pacific Coast Terminals |

Berth Depth | [Insert depth] feet | Varies (generally shallower) |

Crane Capacity | Super post-Panamax | Mix of Panamax and post-Panamax |

On-dock Rail | Yes | Limited availability |

Green Initiatives | Comprehensive | Varies |

Automated Systems | Advanced | Varies |

Conclusion

The West Basin Container Terminal stands as a beacon of efficiency and innovation on the Pacific Coast. By leveraging its advanced infrastructure, cutting-edge technology, and strategic location, WBCT offers shippers unparalleled opportunities to streamline their container operations.

For Pacific Coast shippers looking to optimize their supply chains, understanding and utilizing the capabilities of WBCT is crucial. The strategies and insights provided in this guide can serve as a roadmap for enhancing operational efficiency, reducing costs, and improving overall shipping performance.

As global trade continues to evolve, WBCT remains committed to staying at the forefront of terminal operations. By embracing new technologies, focusing on sustainability, and maintaining strong partnerships with stakeholders, WBCT is well-positioned to meet the challenges of tomorrow’s shipping industry.

Shippers who take full advantage of WBCT’s capabilities and follow the best practices outlined here will find themselves well-equipped to navigate the complexities of Pacific Coast shipping, ensurin