Understanding Dunnage Meaning: Protecting Your Shipments During Transit

What is Dunnage? Defining the Term

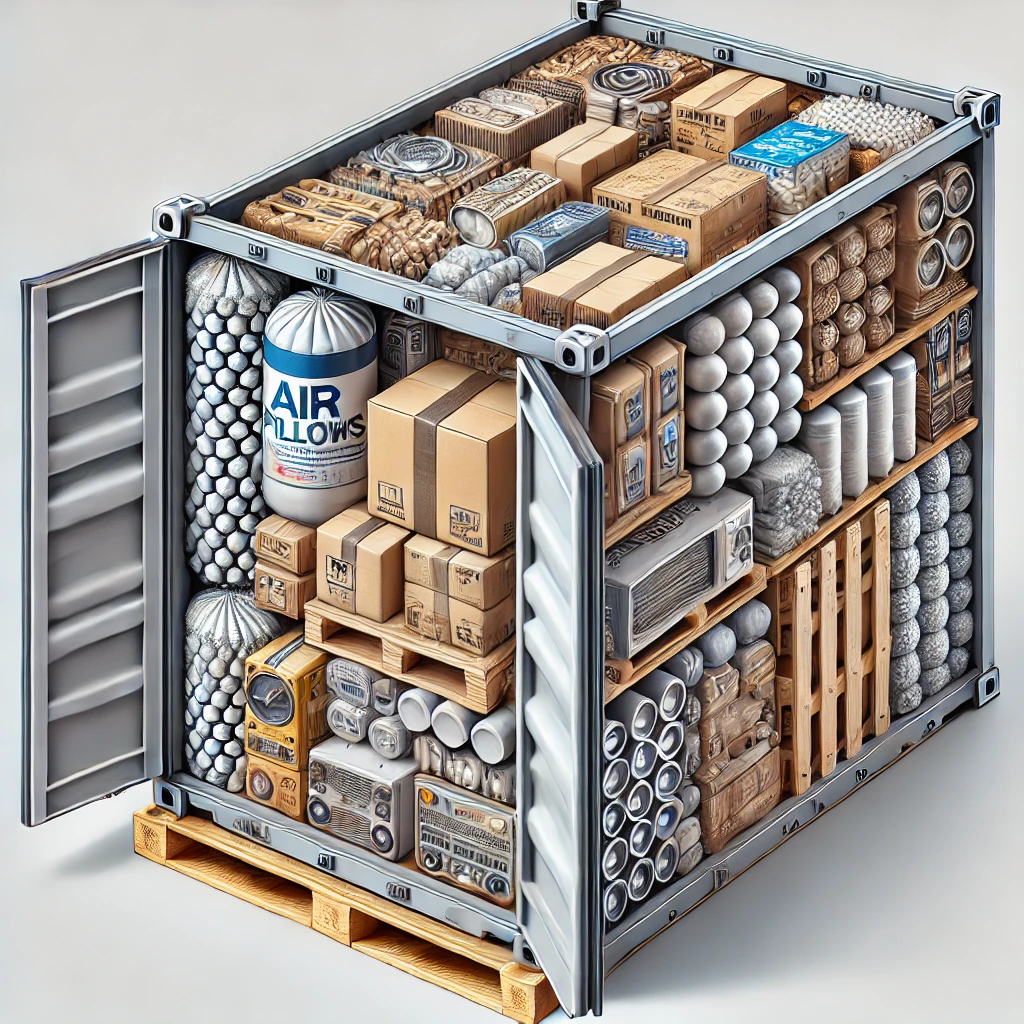

Dunnage refers to the materials used to protect, stabilize, and secure cargo during transportation. These materials are placed around, between, or within shipments to prevent damage from movement, moisture, or contamination. The term “dunnage” has its roots in maritime shipping but has since expanded to encompass all forms of freight transportation.

Key Functions of Dunnage:

- Protection against physical damage

- Absorption of shock and vibration

- Prevention of moisture ingress

- Stabilization of cargo

- Filling of void spaces

- Separation of different products

Understanding the meaning of dunnage is crucial for anyone involved in shipping, as it plays a vital role in minimizing product damage and associated costs.

The Importance of Proper Dunnage

Using appropriate dunnage is not just a matter of following best practices; it’s an essential aspect of responsible shipping that offers numerous benefits:

- Damage Prevention: Properly applied dunnage significantly reduces the risk of product damage during transit, handling, and storage.

- Cost Savings: By preventing damage, dunnage helps avoid the costs associated with product replacement, returns, and customer dissatisfaction.

- Improved Safety: Secure cargo is less likely to shift or fall during transportation, enhancing safety for transport workers and the public.

- Customer Satisfaction: Delivering goods in perfect condition leads to happier customers and fewer complaints.

- Regulatory Compliance: Many industries have specific regulations regarding the secure transportation of goods, which often require the use of appropriate dunnage.

- Environmental Protection: Proper dunnage can prevent spills or leaks of potentially hazardous materials during transport.

Types of Dunnage Materials

There’s a wide variety of dunnage materials available, each suited to different types of cargo and shipping conditions. Here are some of the most common types:

1. Air Pillows Dunnage Meaning

- Description: Inflatable plastic cushions that fill void spaces.

- Best for: Lightweight items, fragile goods.

- Advantages: Lightweight, customizable size, reusable.

2. Foam Sheets and Blocks

- Description: Soft, flexible foam materials used for cushioning.

- Best for: Delicate electronics, glassware, furniture.

- Advantages: Excellent shock absorption, can be cut to size.

3. Corrugated Cardboard Dunnage Meaning

- Description: Sturdy paper-based material with a fluted middle layer.

- Best for: Separating items, creating custom inserts.

- Advantages: Recyclable, cost-effective, easily customizable.

4. Wooden Crates and Pallets

- Description: Sturdy wooden structures for heavy or large items.

- Best for: Industrial equipment, machinery, bulk shipments.

- Advantages: High load-bearing capacity, stackable, reusable.

5. Bubble Wrap

- Description: Plastic sheets with air-filled bubbles for cushioning.

- Best for: Fragile items, odd-shaped products.

- Advantages: Lightweight, flexible, provides visual assurance of protection.

6. Packing Peanuts Dunnage Meaning

- Description: Small, lightweight foam or starch-based pieces.

- Best for: Filling void spaces, cushioning small items.

- Advantages: Conforms to shapes, biodegradable options available.

7. Molded Pulp Dunnage Meaning

- Description: Custom-molded packaging made from recycled paper fibers.

- Best for: Electronics, appliances, fragile items with specific shapes.

- Advantages: Eco-friendly, excellent cushioning, custom-fit protection.

8. Inflatable Dunnage Bags

- Description: Large, inflatable bags used to fill gaps between cargo.

- Best for: Securing loads in trucks, containers, or rail cars.

- Advantages: Adjustable pressure, reusable, prevents load shifting.

Choosing the Right Dunnage for Your Shipments

Selecting the appropriate dunnage meaning is crucial for ensuring the safety of your goods. Here are key factors to consider:

- Nature of the Product: Consider the fragility, weight, and shape of the items being shipped.

- Mode of Transportation: Different transport methods (e.g., road, rail, sea, air) may require specific dunnage solutions.

- Environmental Factors: Consider temperature fluctuations, humidity, and potential exposure to elements during transit.

- Cost-Effectiveness: Balance the cost of dunnage against the value of the goods and potential damage costs.

- Sustainability: Where possible, opt for recyclable or biodegradable dunnage materials.

- Ease of Use: Consider how easily the dunnage can be applied and removed by handlers.

- Regulatory Requirements: Ensure your dunnage choices comply with relevant shipping regulations and industry standards.

Best Practices for Using Dunnage

To maximize the effectiveness of your dunnage and ensure optimal protection for your shipments, follow these best practices:

- Conduct a Thorough Risk Assessment: Analyze potential hazards during transit and select dunnage that addresses these specific risks.

- Use Multiple Dunnage Types: Combine different materials for comprehensive protection (e.g., foam sheets with air pillows).

- Fill All Void Spaces: Ensure there’s no room for items to shift or collide during transport.

- Distribute Weight Evenly: Use dunnage to balance the load and prevent tipping or shifting.

- Protect Edges and Corners: Pay special attention to vulnerable areas of your products.

- Consider Reusability: Where possible, use dunnage that can be returned and reused to reduce waste and costs.

- Train Your Team: Ensure all staff involved in packing and shipping understand proper dunnage techniques.

- Regularly Review and Update: Continuously assess the effectiveness of your dunnage strategies and adapt as needed.

Common Dunnage Mistakes to Avoid

Even with the best intentions, shippers can sometimes make errors in their use of dunnage meaning. Here are some common mistakes to watch out for:

- Underestimating Required Protection: Not using enough dunnage or choosing materials that aren’t sturdy enough.

- Overloading Packages: Exceeding weight limits can compromise the effectiveness of dunnage.

- Ignoring Product-Specific Needs: Using a one-size-fits-all approach instead of tailoring dunnage to specific items.

- Neglecting Environmental Factors: Failing to account for temperature changes, humidity, or potential exposure to elements.

- Poor Application Techniques: Incorrectly applying dunnage, leaving gaps or weak points in protection.

- Overlooking Sustainability: Using non-recyclable materials when eco-friendly alternatives are available.

- Skimping on Quality: Choosing the cheapest option rather than the most appropriate for the task.

The Future of Dunnage: Innovations and Trends

As shipping and logistics continue to evolve, so too does the world of dunnage. Here are some exciting trends and innovations to watch:

- Smart Dunnage: Integration of sensors to monitor shipment conditions in real-time.

- Biodegradable Materials: Development of more eco-friendly dunnage options to reduce environmental impact.

- Custom 3D-Printed Solutions: On-demand creation of tailored dunnage for unique or high-value items.

- Nano-Materials: Advanced materials offering superior protection with minimal weight and bulk.

- Reusable Dunnage Systems: Innovative designs for easily returnable and reusable protective materials.

- AI-Optimized Packing: Use of artificial intelligence to determine the most efficient dunnage configuration for complex shipments.

Conclusion: Elevating Your Shipping Strategy with Proper Dunnage

Understanding the meaning and importance of dunnage is crucial for any business involved in shipping goods. By choosing the right materials and implementing best practices, you can significantly reduce the risk of damage, lower costs, and enhance customer satisfaction.

Remember, effective dunnage is not just about filling empty spaces – it’s about creating a comprehensive protective environment for your products throughout their journey. Whether you’re shipping delicate electronics, heavy machinery, or perishable goods, there’s a dunnage solution that can meet your needs.

As you refine your shipping strategies, make dunnage a top priority. Invest time in selecting the right materials, training your team, and staying informed about the latest innovations in the field. By doing so, you’ll not only protect your shipments but also strengthen your reputation as a reliable and responsible shipper in today’s competitive marketplace.

Are you ready to revolutionize your approach to shipment protection? Start by assessing your current dunnage practices and exploring new materials and techniques that could enhance your shipping operations. With the right dunnage strategy, you can ensure that your products arrive at their destination in perfect condition, every time.