Manufacturing Software for Optimizing Business Operations

Manufacturing software is integral for businesses aiming to optimize their operations, reduce costs, and increase productivity. This guide provides an in-depth look into manufacturing software, highlighting its key features, benefits, and real-world applications. We’ll address common challenges and present practical solutions, helping you make informed decisions about the best software for your manufacturing needs.

Overview of Manufacturing Software

Manufacturing software integrates various tools to streamline production processes, manage inventory, and ensure quality control. It supports manufacturers by providing real-time data, enhancing operational efficiency, and reducing costs.

What is Manufacturing Management software?

Manufacturing software encompasses a suite of tools designed to manage and streamline manufacturing operations. It includes functionalities like inventory management, production scheduling, quality control, and more. These tools help businesses optimize their production processes and ensure product quality.

Why is Manufacturing Software Essential?

In today’s competitive market, efficiency and accuracy are paramount. Manufacturing software provides the visibility and control needed to meet production demands, reduce waste, and enhance overall productivity. It is a crucial component for businesses looking to stay competitive and meet customer expectations.

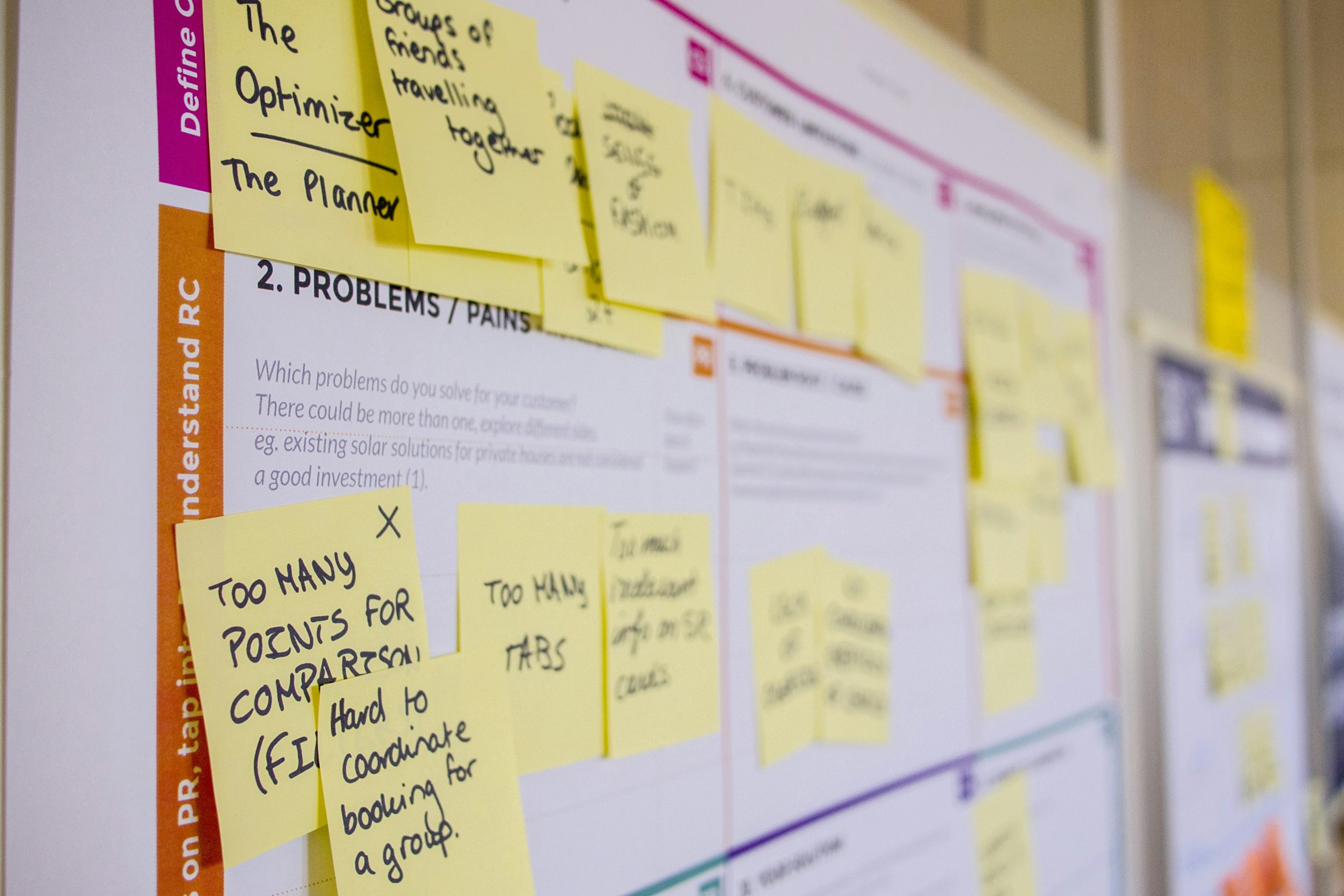

Key Features of Software for Manufacturers

Manufacturing software is designed to streamline various aspects of production, enhance efficiency, and ensure quality control. Below are some essential features that every manufacturing software should include and the reasons why they are critical for modern manufacturing operations.

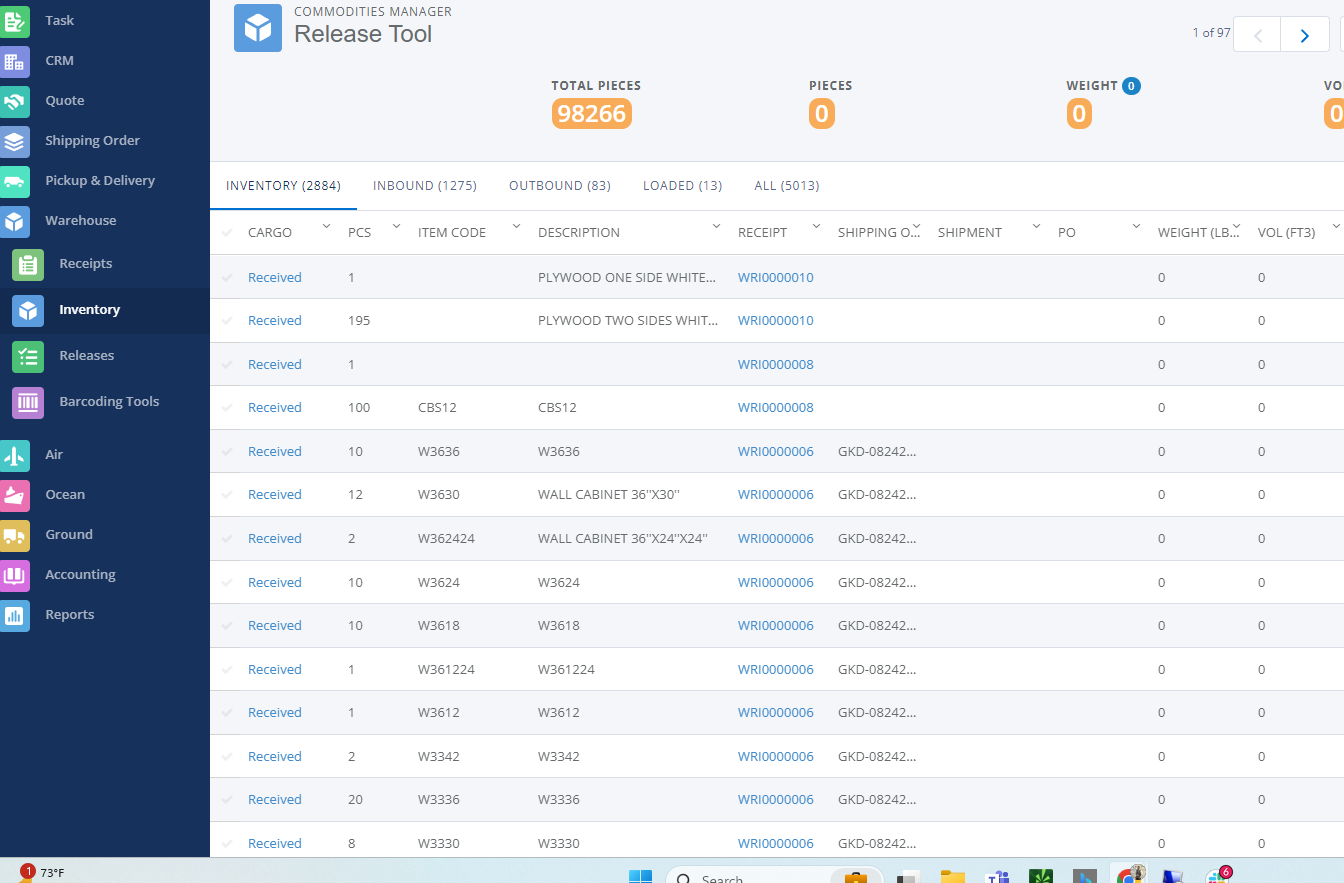

1. Inventory Management

Use: This feature helps track raw materials, work-in-progress, and finished goods in real-time. It ensures that manufacturers maintain optimal inventory levels, reducing the risks of overstocking and stockouts.

Why It’s Used:

- Efficiency: Real-time tracking allows for quick adjustments to inventory levels based on demand.

- Cost Savings: Reduces holding costs by maintaining just-in-time inventory levels.

- Accuracy: Minimizes errors associated with manual inventory tracking.

2. Production Scheduling

Use: Production scheduling tools help plan and manage the production process, ensuring that manufacturing runs smoothly and resources are allocated efficiently.

Why It’s Used:

- Resource Optimization: Ensures that machinery, labor, and materials are used efficiently.

- On-Time Delivery: Helps meet production deadlines by planning production runs effectively.

- Flexibility: Allows for adjustments in production schedules in response to changes in demand.

3. Quality Control

Use: This feature monitors production processes to ensure products meet quality standards, identifying defects and issues early in the manufacturing process.

Why It’s Used:

- Consistency: Maintains high product quality by detecting and addressing defects early.

- Compliance: Ensures that products meet industry regulations and standards.

- Customer Satisfaction: Improves customer satisfaction by delivering high-quality products consistently.

4. Real-Time Data Analytics

Use: Provides real-time insights into various aspects of the manufacturing process, from production rates to equipment performance.

Why It’s Used:

- Informed Decision-Making: Real-time data helps managers make informed decisions quickly.

- Performance Monitoring: Tracks key performance indicators (KPIs) to monitor and improve manufacturing efficiency.

- Predictive Maintenance: Uses data to predict when equipment might fail, allowing for preventive maintenance.

5. Bill of Materials (BOM) Management

Use: BOM management helps in maintaining an accurate list of materials and components required for manufacturing products.

Why It’s Used:

- Accuracy: Ensures that all necessary materials are available for production.

- Cost Control: Helps manage material costs by providing an accurate breakdown of components.

- Production Planning: Facilitates efficient production planning by detailing all required materials.

6. Supply Chain Management

Use: Manages interactions with suppliers, tracks materials, and coordinates logistics to ensure timely delivery of materials.

Why It’s Used:

- Coordination: Enhances coordination with suppliers and logistics partners.

- Efficiency: Streamlines the supply chain to reduce lead times and costs.

- Visibility: Provides end-to-end visibility of the supply chain, improving overall efficiency.

7. Customer Relationship Management (CRM)

Use: Integrates customer data to help manage relationships, track orders, and provide post-sale support.

Why It’s Used:

- Customer Insights: Offers valuable insights into customer behavior and preferences.

- Sales Management: Tracks sales and order history to improve sales processes.

- Support: Enhances post-sale support and customer satisfaction.

8. Financial Management

Use: Handles all financial transactions, including accounting, budgeting, and financial reporting.

Why It’s Used:

- Accuracy: Ensures accurate financial tracking and reporting.

- Cost Management: Helps manage costs and budgeting efficiently.

- Compliance: Ensures compliance with financial regulations and standards.

9. Human Resources Management (HRM)

Use: Manages employee data, payroll, recruitment, and performance evaluations.

Why It’s Used:

- Efficiency: Streamlines HR processes, reducing administrative burden.

- Employee Management: Tracks employee performance and manages payroll accurately.

- Compliance: Ensures compliance with labor laws and regulations.

10. Integration Capabilities

Use: Ensures that the manufacturing software can integrate seamlessly with other enterprise systems, such as ERP, CRM, and SCM systems.

Why It’s Used:

- Data Consistency: Ensures data consistency across various systems.

- Efficiency: Reduces data entry efforts and improves overall process efficiency.

- Scalability: Allows for scalable solutions that can grow with the business.

Benefits of Using Manufacturing Software: Real-Life Examples Across Industries

Manufacturing software offers numerous benefits that can transform business operations, from improving efficiency to reducing costs and enhancing overall productivity. Here, we explore these benefits with real-life examples across various industries.

1. Improved Efficiency

Example: Automotive Industry

In the automotive industry, companies like Toyota have leveraged manufacturing software to streamline their production processes. By implementing real-time inventory tracking and production scheduling, Toyota has been able to reduce downtime and optimize the use of resources. This has led to faster production cycles and a significant increase in throughput.

Key Benefit:

- Streamlined Operations: Real-time data helps identify bottlenecks and inefficiencies, allowing for immediate corrective actions.

2. Cost Reduction

Example: Electronics Manufacturing

An electronics manufacturer, Samsung, utilized manufacturing software to optimize their inventory management. By maintaining just-in-time inventory levels, Samsung reduced holding costs and minimized the risk of overproduction. This approach not only cut down on waste but also improved cash flow.

Key Benefit:

- Lower Operational Costs: Efficient inventory management reduces costs associated with excess inventory and storage.

3. Enhanced Productivity

Example: Food and Beverage Industry

In the food and beverage sector, companies like Nestlé have adopted manufacturing software for food and beverage to automate routine tasks and provide real-time data insights. This automation has allowed employees to focus on more strategic activities, boosting overall productivity and business performance.

Key Benefit:

- Increased Output: Automation and real-time insights enable better resource allocation and higher productivity levels.

4. Quality Control

Example: Pharmaceutical Industry

Pharmaceutical companies like Pfizer use manufacturing software to monitor production processes closely and ensure compliance with stringent quality standards. The software helps in tracking defects and maintaining product consistency, which is crucial for regulatory compliance and customer satisfaction.

Key Benefit:

- Consistent Quality: Monitoring and early detection of defects ensure that products meet high-quality standards consistently.

5. Better Decision Making

Example: Aerospace Industry

In the aerospace industry, Boeing utilizes manufacturing software to gather and analyze data from various production stages. This data-driven approach helps in making informed decisions that enhance operational efficiency and product quality.

Key Benefit:

- Informed Decisions: Real-time data analytics provide valuable insights for strategic planning and operational improvements.

6. Compliance and Traceability

Example: Medical Device Manufacturing

Companies like Medtronic in the medical device manufacturing sector use manufacturing software to maintain detailed records of their production processes. This traceability is crucial for compliance with industry regulations and for ensuring the safety and efficacy of their products.

Key Benefit:

- Regulatory Compliance: Detailed tracking and documentation help in meeting industry standards and regulatory requirements.

Comparison with Competitors Unique Features of Linbis Distribution Management Software

While many manufacturing software solutions offer similar features, Linbis stands out with its comprehensive distribution management software capability. Our software integrates seamlessly with manufacturing processes, providing end-to-end visibility and control over the supply chain.

Seamless Integration

Linbis offers seamless integration with existing systems, ensuring a smooth transition and minimal disruption to your operations.

User-Friendly Interface

Our software features an intuitive interface that makes it easy for users to navigate and utilize its full potential.

Why Choose Linbis?

Linbis provides robust analytics, excellent customer support, and adaptability to unique business needs, ensuring optimal performance and user satisfaction. Our software is designed to help businesses achieve greater efficiency, reduce costs, and enhance productivity.

Conclusion

Manufacturing software is essential for improving efficiency, reducing costs, and boosting productivity. By choosing the right software, businesses can achieve significant operational improvements and stay competitive in the market. Contact Linbis today to learn more about our powerful distribution management software and request a demo.