Exploring Supply Chain Optimization in Detail

This article provides a detailed explanation of supply chain optimization, highlighting key features, benefits, strategies, and its relevance for businesses.

What Is Supply Chain Optimization?

Supply chain optimization refers to the systematic improvement of supply chain processes to achieve maximum efficiency and minimal costs while maintaining high service levels. It involves:

- Reducing logistics costs

- Enhancing inventory management

- Improving supplier relationships

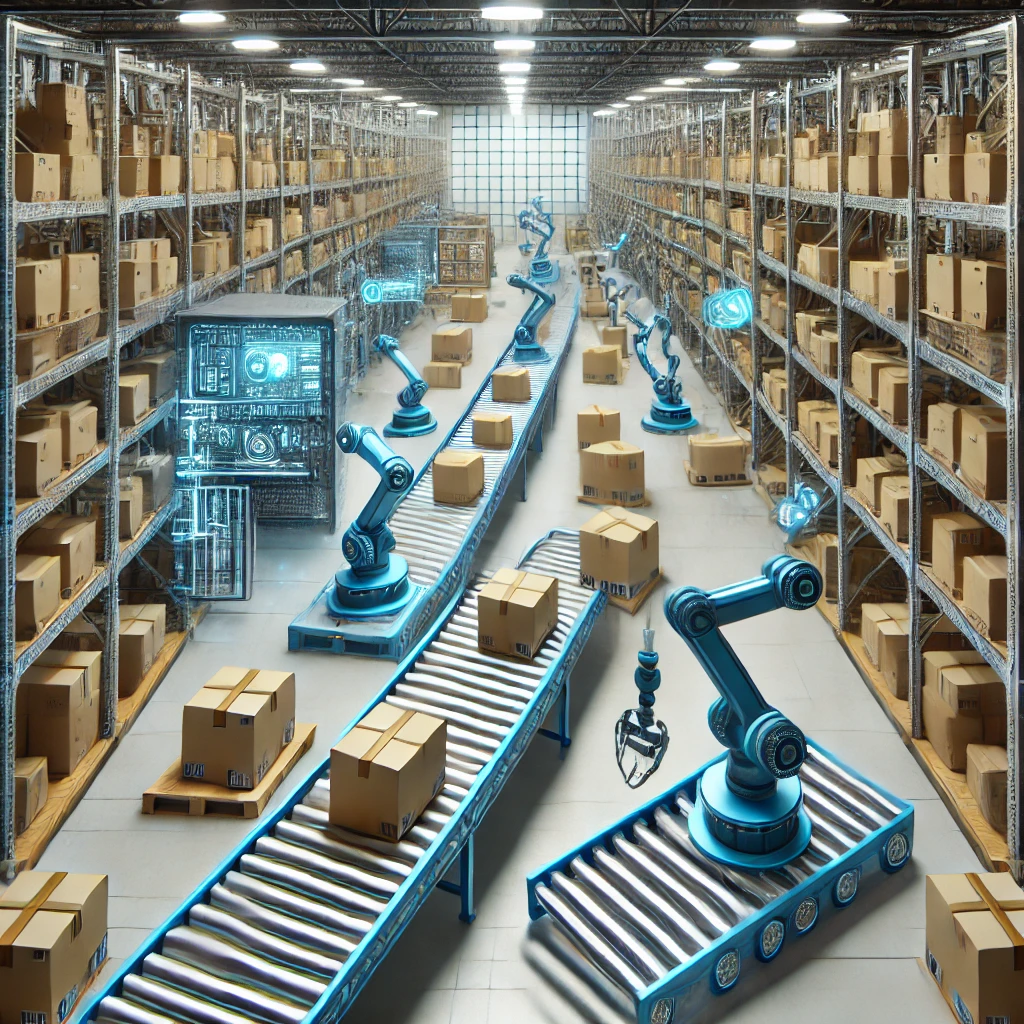

- Streamlining warehouse operations

- Leveraging digital tools and automation

Key Components of Supply Chain Optimization

Component | Description |

Inventory Optimization | Ensuring the right stock levels to meet demand while minimizing costs. |

Transportation Management | Choosing the most efficient shipping methods and routes. |

Supplier Relationship Management | Strengthening partnerships for better pricing and reliability. |

Warehouse Efficiency | Optimizing storage, automation, and fulfillment speed. |

Demand Forecasting | Using data analytics to predict market needs. |

Technology Integration | Implementing AI, IoT, and cloud-based solutions for better visibility. |

How Does Supply Chain Optimization Work?

1. Demand Forecasting & Planning

- Uses historical sales data, market trends, and AI models to predict future demand.

- Helps businesses avoid stockouts and overstocking.

2. Inventory & Warehouse Optimization

- Implements automated inventory management systems.

- Ensures optimal stock levels across multiple locations.

3. Transportation & Logistics Efficiency

- Optimizes shipping routes and modes (air, sea, road, rail).

- Reduces transportation costs and delays.

4. Supplier & Procurement Strategy

- Develops long-term relationships with reliable suppliers.

- Ensures timely delivery of raw materials and finished goods.

5. Digital Transformation & AI-Driven Analytics

- Uses IoT sensors for real-time tracking of shipments.

- Applies AI-driven insights for predictive analytics and risk management.

Practical Applications of Supply Chain Optimization

1. E-Commerce & Retail Industry

- Improves inventory accuracy and fulfillment speed.

- Enhances customer satisfaction with faster delivery.

2. Manufacturing & Production

- Reduces waste and inefficiencies in production scheduling.

- Ensures just-in-time (JIT) inventory management.

3. Healthcare & Pharmaceutical Supply Chains

- Maintains steady supply of medical equipment and drugs.

- Prevents shortages and delays in critical care supplies.

4. Food & Beverage Logistics

- Optimizes cold chain management for perishable goods.

- Reduces spoilage and enhances food safety compliance.

5. Automotive & Heavy Machinery Supply Chains

- Streamlines global procurement of raw materials and components.

- Reduces lead times in production and assembly.

Supply chain optimization refers to the systematic improvement of supply chain processes to achieve maximum efficiency and minimal costs while maintaining high service levels. It involves:

- Reducing logistics costs

- Enhancing inventory management

- Improving supplier relationships

- Streamlining warehouse operations

- Leveraging digital tools and automation

Advantages and Challenges of Supply Chain Optimization

Advantages | Challenges |

Reduces operational costs through efficiency improvements. | Requires investment in advanced technology and training. |

Improves order fulfillment speed and customer satisfaction. | Supply chain disruptions (e.g., pandemics, political instability). |

Enhances supplier and inventory management. | Complex logistics coordination across multiple regions. |

Minimizes waste and optimizes warehouse operations. | Data security risks in digital supply chain management. |

Supply Chain Optimization vs. Traditional Supply Chain Management

Aspect | Traditional Supply Chain | Optimized Supply Chain |

Inventory Control | Manual tracking, higher excess stock. | AI-driven demand forecasting, lean inventory. |

Logistics Management | Standard shipping routes. | Route optimization, dynamic pricing. |

Technology Usage | Limited automation. | IoT, AI, and cloud-based tracking. |

Cost Efficiency | Higher transportation and warehousing costs. | Reduced costs through efficiency and automation. |

Strategies for Implementing Supply Chain Optimization

✅ 1. Leverage AI & Machine Learning for Predictive Analytics

- Uses historical data to optimize supply chain decisions.

- Predicts demand fluctuations and market trends.

✅ 2. Automate Inventory & Warehouse Management

- Implements robotics and RFID tracking in warehouses.

- Reduces manual errors and speeds up order fulfillment.

✅ 3. Implement Data-Driven Transportation Management Systems (TMS)

- Selects optimal shipping routes and carriers.

- Reduces transportation delays and costs.

✅ 4. Strengthen Supplier & Vendor Collaboration

- Uses blockchain technology for transparency.

- Ensures timely raw material sourcing.

✅ 5. Focus on Sustainable & Green Supply Chains

- Reduces carbon footprint with eco-friendly logistics.

- Implements circular supply chain strategies.

When Should a Business Optimize Its Supply Chain?

- If logistics costs are increasing rapidly.

- When customer demand is fluctuating unpredictably.

- If warehouse space is underutilized or overstocked.

- When international trade regulations affect supply chain movement.

Conclusion

Supply chain optimization is essential for businesses looking to enhance operational efficiency, reduce costs, and improve customer satisfaction. By leveraging technology, automation, and strategic planning, companies can build a resilient and future-proof supply chain.

With AI-powered analytics, digital tracking, and smart logistics solutions, businesses can navigate global challenges, prevent disruptions, and maximize profitability—making supply chain optimization a critical aspect of modern commerce.